ESD primer and intermediate coat & ASD topcoat and single-coat

| Name | TM | SDB |

|---|---|---|

|

ESD 182 K-DB

2C EP high solid active primer for interior and exterior coating of transformer tanks made of steel, aluminium and galvanized steel (sweep-blasted)

| ||

|

ESD 152

2C EP high solid zinc dust primer, Zn (R), for steel (blasted)

| ||

|

ESD 156

2C EP high solid zinc dust primer, economical formulation with a special zinc dust/active pigment combination for steel (blasted)

| ||

|

ESD 155

2C EP high solid zinc flake primer with reduced zinc content for steel

| ||

|

ESD 30/33

2C-EP high solid MIO intermediate coat

| ||

|

ASD 43

2C-PUR high solid (mica) topcoat

| ||

|

ASD 47

2C-PUR high solid (mica) topcoat

| ||

|

ASD 08

2C-PUR high solid active single-coat paint (DTM) for steel (blasted) and galvanized steel (sweep-blasted)

| ||

|

ESD 182 / 7016 K

2C EP high solid active primer for transformer core laminations, steel, aluminium and galvanized steel (sweep-blasted); heat resistant up to 180 °C

|

|

|

Product informations

- low VOC, solvent-based system

- 2-component system with thermoplastic properties

- ESD epoxy-based primer and intermediate coat crosslinked with amine-based hardener

HIGHLIGHT

- ESD 182 K-DB is compatible with common insulating liquids used in transformers; suitable for use as an interior and exterior coating for transformer tanks due to its excellent corrosion protection properties

- ESD 155 is based on zinc flake technology which creates a synergistic effect combining cathodic corrosion protection with an effective barrier function. The cathodic protection of ESD 155 is achieved with a significantly lower zinc content compared to conventional Zn (R) primers, such as ESD 152 (zinc content reduced by up to 60 %)

- ESD 182/7016 K is suitable for transformers; excellent corrosion protection properties and adhesion to core laminations; temperature resistance up to 180 °C; film thicknesses of 120–160 µm achievable in a single spray pass

- ASD polyurethane-based topcoat and single-coat crosslinked with isocyanate-based hardener

HIGHLIGHT

- ASD 08 has good corrosion protection properties on its own; for higher corrosion protection requirements, it can be used as topcoat in combination with ESD

- spray, brush and flow coating

- excellent corrosion protection properties

- excellent UV and weather resistance

- good mechanical and chemical resistance

- relatively short pot life (2-component spray equipment recommended)

- fast drying time enables efficient processing times

- application and good drying even at low temperatures down to +3 °C

- good cost-performance ratio

- high coverage

- certificate confirming compatibility of ESD 182 K-DB with insulating liquids available

RWE primer, intermediate coat and topcoat

| Name | TM | SDB |

|---|---|---|

|

RWE-GB-14-S

2C EP high solid zinc dust primer for steel (blasted)

| ||

|

RWE-GB-20-S

2C AK high-solid active primer for steel (blasted)

| ||

|

RWE-GB-21-S

2C EP high solid MIO primer for galvanized steel (sweep-blasted)

| ||

|

RWE-ZB-22-S

2C EP high solid MIO intermediate coat

| ||

|

RWE-DB-23-S

2C PUR high solid MIO intermediate coat and topcoat

| ||

|

RWE-DB-24-S

2C PUR high solid topcoat

|

Product informations

- solvent-based, low VOC system approved by RWE

- low-solvent, 2-component systems with thermoplastic properties

- epoxy-based primers and intermediate coats crosslinked with amine-based hardeners

- polyurethane-based intermediate coats and topcoats crosslinked with isocyanate-based hardeners

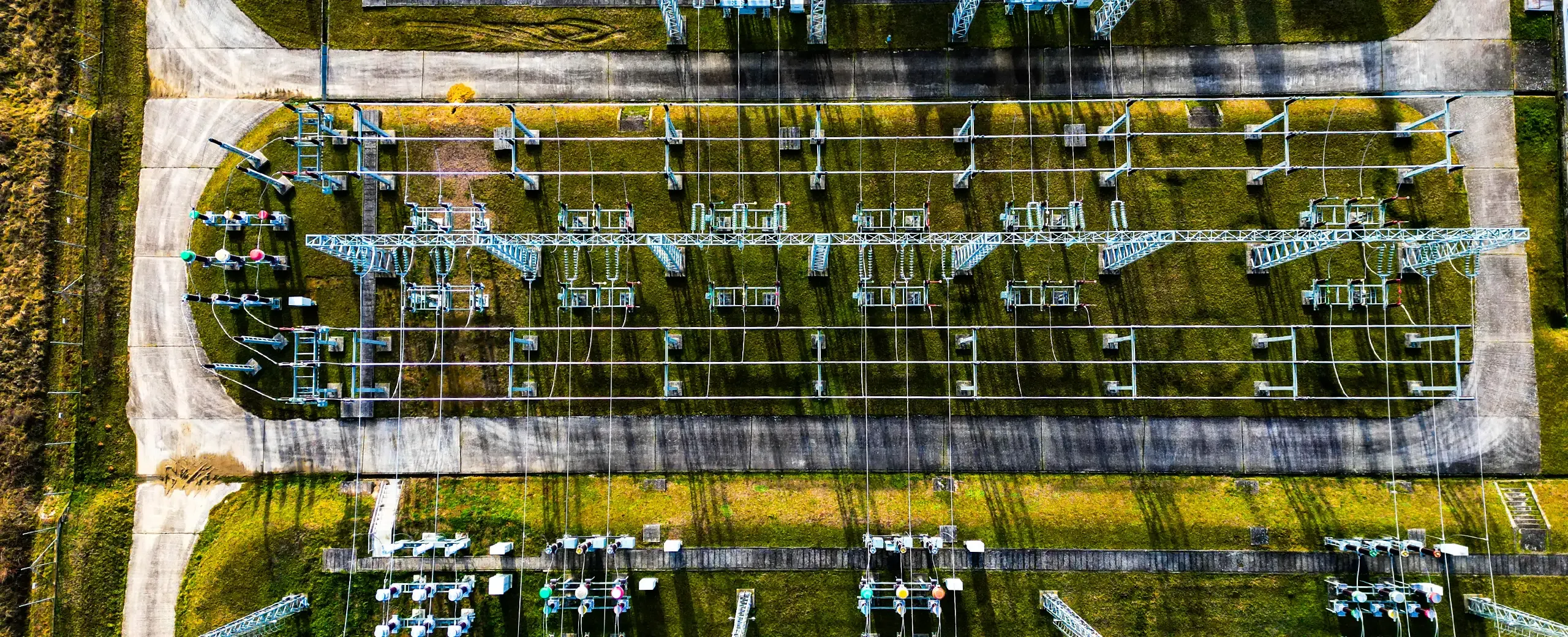

- high-resistance coating materials designed for heavy-duty corrosion protection of steel structures (e.g. power plant construction); use on steel (blasted) and hot-dip galvanized steel (sweep-blasted)

- spray and brush application

- excellent corrosion protection properties

- excellent UV and weather resistance

- high mechanical and chemical resistance

- moderate pot life

- fast drying time enables efficient processing times

- cost-effective solution

- high coverage

- RWE approval according to RWE directive available

- test reports for qualification of the RWE 1C HYDRO coating products available

Blatt 95 according to TL/TP-KOR-Stahlbauten

Produktinformationen

- Lösemittelbasiertes System mit Zulassung der Bundesanstalt für Straßenbau (BASt) – „niedriger VOC“

- Lösemittelarme 2-Komponenten-Systeme mit duroplastischen Eigenschaften

- Grund- und Zwischenbeschichtungen auf Epoxidharzbasis vernetzt mit Härtern auf Amin-Basis

- Zwischen- und Deckbeschichtungen auf Polyurethanbasis vernetzt mit Härtern auf Isocyanat-Basis

- Beschichtungsstoffe mit hoher Beständigkeit für den schweren Korrosionsschutz von Stahlbauten (z.B. Brücken- und Straßenbau); Einsatz auch auf feuerverzinkten Stahl (gesweept) sowie spritzverzinktem Stahl möglich

- Verarbeitung durch Spritz- und Streichapplikation möglich

- Hervorragende Korrosionsschutzeigenschaften

- Exzellente Licht- und Wetterbeständigkeit

- Hohe mechanische und chemische Beständigkeit

- Moderate Topfzeit

- Schnelle Trocknungszeit ermöglicht effiziente Prozesszeiten

- Gutes Preis-Leistungsverhältnis

- Hohe Ergiebigkeit

- Zulassung der Bundesanstalt für Straßenbau (BASt) nach TL/TP-KOR-Stahlbauten verfügbar

- Prüfbericht für Blatt 95 gemäß TL/TP-KOR-Stahlbauten, Anhang E verfügbar